Brazing aluminum foils/plates are widely used in the manufacture of various heat exchangers.

The Aluminum-based solder, Al-Si alloy has a low melting point, good fluidity, which makes it suitable for solder. Typical aluminum-based solder is 4343 aluminum alloy , 4045 (ASTM) aluminum alloy and 4004 aluminum alloy.

Industrial pure aluminum (1000 series aluminum ), Al-Mn alloys, and 6951(ASTM) aluminum alloy in Al-Mg-Si alloys have good brazing properties and can be brazed with the above-mentioned aluminum-based brazing materials.

6061,6053 (ASTM) and 6063 aluminum alloy the also have good brazing properties, but because their initial melting temperatures are lower than those of industrial pure aluminum and Al-Mn alloys.Thus the brazing temperature must be strictly controlled to prevent excess of proper temperature. 4004 aluminum alloy solder contains magnesium; it is suitable for vacuum brazing.In the brazing process,by the reaction of the furnace residual oxygen and water, magnesium vapor plays a role of purification. Magnesium vapor can also inhibit the re-oxidation of brazing aluminum alloy.

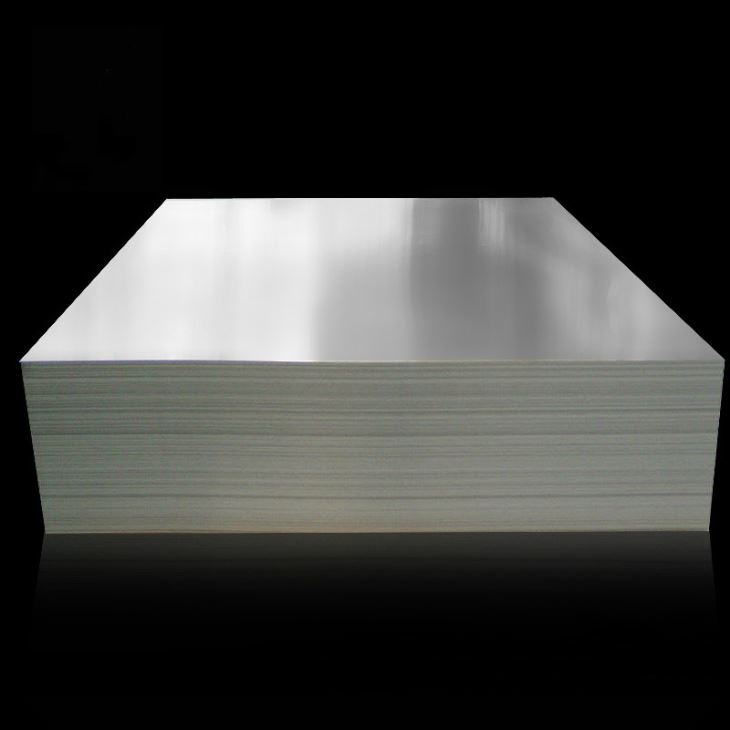

Aluminum alloy brazing plate is usually made of aluminum manganese alloy (3A21,3003 aluminum alloy ) core material and aluminum-based solder cladding composite panel. The aluminum-based solder is placed on one or both sides of the core ingot and preheated to the hot rolling temperature (about 500 °C). After hot rolling, then it will be cold-rolled into a sheet, and the coating is completely pressed to the core material. The thickness of the cladding layer is 5% to 15% of the thickness of the core material.

Aluminum alloy brazing plates are usually used as a component of the brazing assembly and the other part is an unclad, braze-able aluminum alloy material. When it is brazed, the entire assembly will be put into the furnace or undergo a salt bath and evenly heated to high temperature.The solder on brazing plate will melt, by capillary and gravity flow, it will fill the parts where connection is required.

Related products: 3003 amd 4343 aluminum coil for condenser fins

Related News

- A Brief Introduction to Aluminu

- How to choose aluminum bus bar

- Aluminum Bus Bar Arrangement :O

- Aluminum Foil for Tranfo Your B

- Aluminum Foil for Electrolytic

- Aluminum in Electrical Industry

- What Is Brazing Aluminum ?

- How to Prevent Aluminum Foil Fr

- Do you know What are the alumin

- 8011 Aluminum Foil and Its Appl

- EC grade Aluminum Busbar

- Copper Windings Or Aluminum Win

- Composite Brazing Aluminum Tech

- Different Characters of 1xxx al