The grade of aluminum strip for transformers are A1060 A1050, A1060,A1070,A1100, A1350,and the temper is O which means that the aluminum strip is soft. And the number followed the temper shows its hardness and and the degree of annealing( for instance 1060(O-H16)).The thickness of aluminum strip is between 0.08mm-3.00mm,known as aluminum foil/stirp/coil for dry-type transformers .

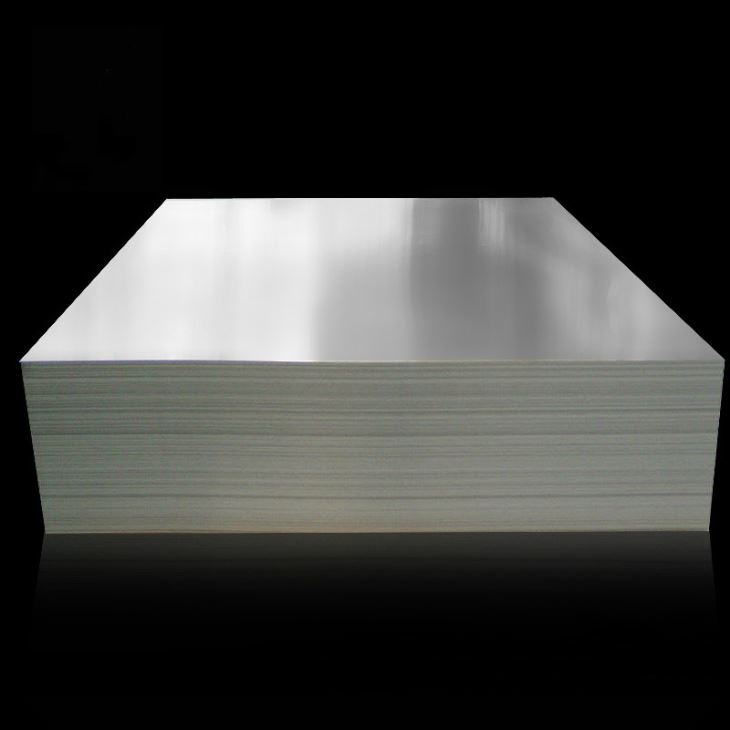

Aluminum foil/stirp/coil for dry-type transformers is high-quality pure aluminum raw material, with high conductivity, soft temper, smooth surface, and without burrs.It is the ideal material for dry-type transformers winding.

Conductive properties for different metals form high to low are as follow :

silver, copper,gold ,aluminum,nickel,steel.

Aluminum is the only base metal whose conductivity and thermal conductivity is just follows that of copper.As the price of copper is much higher than that of aluminum,aluminum foil/strip is widely used for transformers

Aluminum foil/strip for transformers generally is 1060 aluminum strip whose aluminum content is more than 99.6%, and is known as pure aluminum.

The advantages of 1060 aluminum:

1.It is the most commonly used aluminum material.

2.Manufacturing technique is relatively simple.

3.Its price is cheaper than other aluminum material.

3.High elongation strength and tensile strength.

4.With excellant moldability,it is fully able to meet the conventional processing requirements ( stamping, stretching and the like).

5.As the industrial pure aluminum, it is of high plasticity, good corrosion resistance,high electrical conductivity and thermal conductivity.

6.Gas welding, hydrogen welding and resistance welding (or contact welding ) are acceptable.

7.It can bear the pressure processing and extension,bending.

Disadvantages:

1.Its he strength is low and heat treatment can not strengthen it.

2.Its machinability is not good.

3.Not suitbale for brazing.

Previous: No Information

Related News

- A Brief Introduction to Aluminu

- How to choose aluminum bus bar

- Aluminum Bus Bar Arrangement :O

- Aluminum Foil for Tranfo Your B

- Aluminum Foil for Electrolytic

- Aluminum in Electrical Industry

- What Is Brazing Aluminum ?

- How to Prevent Aluminum Foil Fr

- Do you know What are the alumin

- 8011 Aluminum Foil and Its Appl

- EC grade Aluminum Busbar

- Copper Windings Or Aluminum Win

- Composite Brazing Aluminum Tech

- Different Characters of 1xxx al