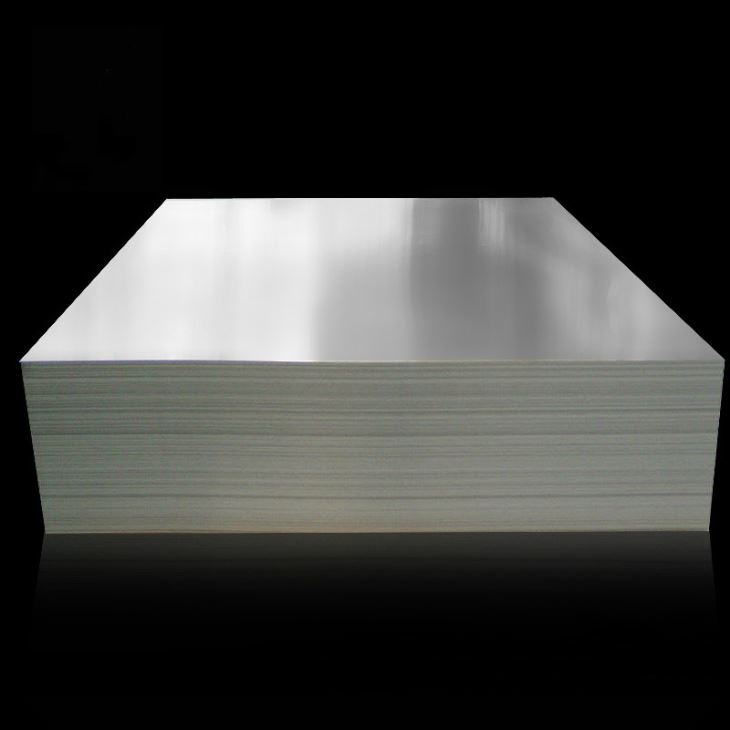

The composite brazing aluminum foil is mainly used for automobile heat exchanger .Al-Mn system alloy is the core material , with brazing Al-Si (usually it thickness is of 10% the foil’s thickness )in double sides

The heat exchanger fins, which are required to withstand high-temperature conditions, have strict quality standards. The original material is supposed to be with excellent surface quality, accurate size and flatness of the shape.Meanwhile it should be of good homogeneous, good formability. The cladding layer uniformity and welding requirements are extremely stringent.

In the process of compound brazing aluminum foil, the key point is to strictly control the surface treatment of sheet metal, heating temperature, rolling compound regulation and heat treatment technology. At present, the domestic research on metal surface treatment has been in a mature stage. Heating in different temperatures and differential deformation rolling composite technology has also been applied to industrial production.The application of these new technologies fully ensures the composite brazing aluminum foil technology advanced and reliability.

In the development of automobile industry, pollution has become a big problem. The use of composite brazing aluminum foil technology for the production of automotive heat exchanger will pollute the environment. First, the scrap recycling of metal ingot milling surface has no pollution to the environment.Second, the surface treatment of the plate is also equipped with dust-absorbing device . At the same time, 90%of the cooling water used in rolling equipment and other equipment can be recycled,.The waste water is non-toxic and meet the discharge standards .

Related News

- A Brief Introduction to Aluminu

- How to choose aluminum bus bar

- Aluminum Bus Bar Arrangement :O

- Aluminum Foil for Tranfo Your B

- Aluminum Foil for Electrolytic

- Aluminum in Electrical Industry

- What Is Brazing Aluminum ?

- How to Prevent Aluminum Foil Fr

- Do you know What are the alumin

- 8011 Aluminum Foil and Its Appl

- EC grade Aluminum Busbar

- Copper Windings Or Aluminum Win

- Composite Brazing Aluminum Tech

- Different Characters of 1xxx al