1050 aluminium is an aluminium-based in the "commercially pure" wrought family (1000 or 1xxx series). It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manufacture of heat sinks, since it has a higher thermal conductivity than other alloys. It has low mechanical strength compared to more significantly alloyed metals.

Owing to the good conductivity and good price,1050 aluminium foils are widely used for dry type transformer windings in recent years.

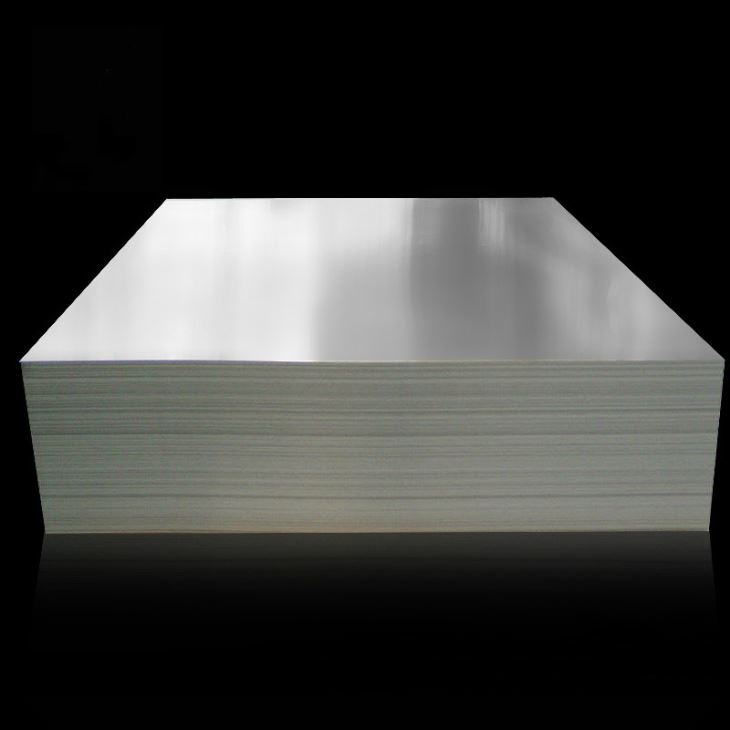

Feature of 1050 (O)aluminum foil

1.Thin and light;

2.Super extractive;

3.Good mechanical strength;

4.High thermal conductivity and electric conductivity;

5.Excellent silvery white luster,beautiful appearance.

Related News

- A Brief Introduction to Aluminu

- How to choose aluminum bus bar

- Aluminum Bus Bar Arrangement :O

- Aluminum Foil for Tranfo Your B

- Aluminum Foil for Electrolytic

- Aluminum in Electrical Industry

- What Is Brazing Aluminum ?

- How to Prevent Aluminum Foil Fr

- Do you know What are the alumin

- 8011 Aluminum Foil and Its Appl

- EC grade Aluminum Busbar

- Copper Windings Or Aluminum Win

- Composite Brazing Aluminum Tech

- Different Characters of 1xxx al