Aluminum has less than one-third the density of copper and, making allowance for conductivity, an aluminum bus bar will weigh about half as much as copper for equal conductance.For large installations requiring millions of pounds of metal, bus system designers have used the low cost of aluminum as the basis for optimum economic current density.

1000 series Al is a commercial high-purity aluminum with 61 percent conductivity. The tensile strength of each 1350 temper is determined by the amount of work given the metal during fabrication.

High electrical conductivity alloys are the best choice for heavy duty buses for the electrochemical industry where cost of power is an important consideration. For outdoor high voltage substation buses, mechanical considerations rather than electrical, govern the selection. Where bending and forming characteristics are important, it is desirable to have a generous spread between yield strength and tensile strength.

Aluminum bus conductors can be formed by the same procedures and practices that are used for other metals.

The most important factors governing the bending of bus conductors are:

(I) the ductility of the conductor

(2) the size and shape of the conductor

(3) the method of bending,and

(4) the bending equipment used.

A metal must be ductile enough to permit both stretching and compression to take place. However, elongation alone is not a complete criterion for ductility. The ratio of yield strength to tensile strength must also be taken into account.A combination of a high elongation value and a low ratio of yield strength to tensile strength provides the most satisfactory ductility.Another factor that governs bending is the size and shape of the bus conductor. For example, in the case of a tube, the sharpness of a bend depends not only on the diameter of the tube, but also on the ratio of wall thickness to diameter.

Resistance to Corrosion Aluminum bus is highly resistant to corrosion. Its uses are, therefore, particularly widespread in applications where strong atmospheric corrosive factors are at work, as in industrial and chemical plants and seacoast environments.

Aluminum has less than one-third the density of copper and, making allowance for conductivity, an aluminum bus bar will weigh about half as much as copper for equal conductance.For large installations requiring millions of pounds of metal, bus system designers have used the low cost of aluminum as the basis for optimum economic current density.

1000 series Al is a commercial high-purity aluminum with 61 percent conductivity. The tensile strength of each 1350 temper is determined by the amount of work given the metal during fabrication.

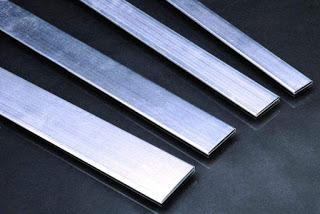

Bus Conductor Shapes

Choice of a bus conductor shape for a given installation is dependent on a number of factors, including operating voltage, ampacity requirements. available short circuit cur bus conductor design and applications rents, available space, mechanical strength requirements,ambient conditions of sun, wind, ice, etc.

The most common form of bus conductor is bar stock of rectangular cross section. This shape is inherently easy to fabricate, store, handle and erect. A relatively large surface area can be provided for the dissipation of heat by the use of multiple-bar buses. Joints and taps are readily made by either bolting or welding.Off-sets and 90-degree bends are easily made.For direct current, as well as for alternating current up to certain limits, the capacity of a bus constructed of flat bar can be controlled by merely varying the size of bars or number of bars in parallel. For high-amperage alternating current, however, special arrangements of laminations are used Because bars are mare rigid in the direction of the large cross-sectional axis, supports must be more closely spaced to resist load and short-circuit forces that are applied perpendicular to the wider surface.

Buy aluminum bus bar, please contact us.

Email : anna@kunyaocn.com

Whats App/Mobile: +86 157 379 25221

Related News

- A Brief Introduction to Aluminu

- How to choose aluminum bus bar

- Aluminum Bus Bar Arrangement :O

- Aluminum Foil for Tranfo Your B

- Aluminum Foil for Electrolytic

- Aluminum in Electrical Industry

- What Is Brazing Aluminum ?

- How to Prevent Aluminum Foil Fr

- Do you know What are the alumin

- 8011 Aluminum Foil and Its Appl

- EC grade Aluminum Busbar

- Copper Windings Or Aluminum Win

- Composite Brazing Aluminum Tech

- Different Characters of 1xxx al