1.Bauxite

Aluminium production starts with the raw material bauxite, a clay like soil type found in a belt around the equator. The bauxite is mined from a few meters below the ground.

Bauxite grinder

The bauxite is then transported to plants where the clay is washed off and the bauxite passes through a grinder.

2.Alumina

Alumina, or aluminium oxide, is extracted from the bauxite through refining.

Refining process

Alumina is separated from the bauxite by using a hot solution of caustic soda and lime.

3.Pure alumina

The mixture is heated and filtered, and the remaining alumina is dried to a white powder.

4.Processing

Next stop is the metal plant. Here, the refined alumina is transformed into aluminium.

Refinement process

Three different raw materials are needed to make aluminium, aluminium oxide, electricity and carbon.

Electricity is run between a negative cathode and a positive anode, both made of carbon. The anode reacts with the oxygen in the alumina and forms CO2.The result is liquid aluminium, which can now be tapped from the cells.

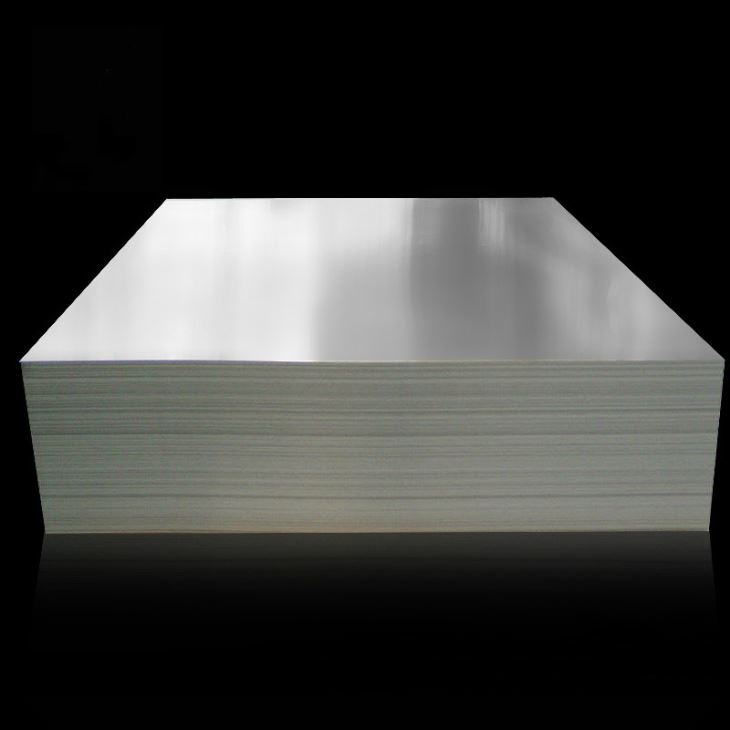

5.Rolling

Aluminium is very ductile. Foil can be rolled from 60 cm to 2-6 mm, and final foil product can be as thin

as 0.006 mm. It still will not let light, aroma or taste in or out.

6.Process

Sheet ingots are used to make rolled products, such as plates, strip and foil.

Previous: Aluminum Used for Bicycle

Related News

- What is Waterstain on Aluminum

- Why Aluminum Alloy For Automobi

- A Brief Introduction for Pure A

- The Difference of Mechanical Wo

- Pattern aluminum-related knowle

- Sectionalized Double Bus Bar

- Aluminum in Transport

- Aluminum Used for Bicycle

- How to Make Aluminum Foil ?

- What Are Aluminum Alloys for Bi

- Properties of Aluminum

- Aluminum and Aluminum Alloy's A

- How to Calculate the Weight of

- Why Anodization for Aluminum ?