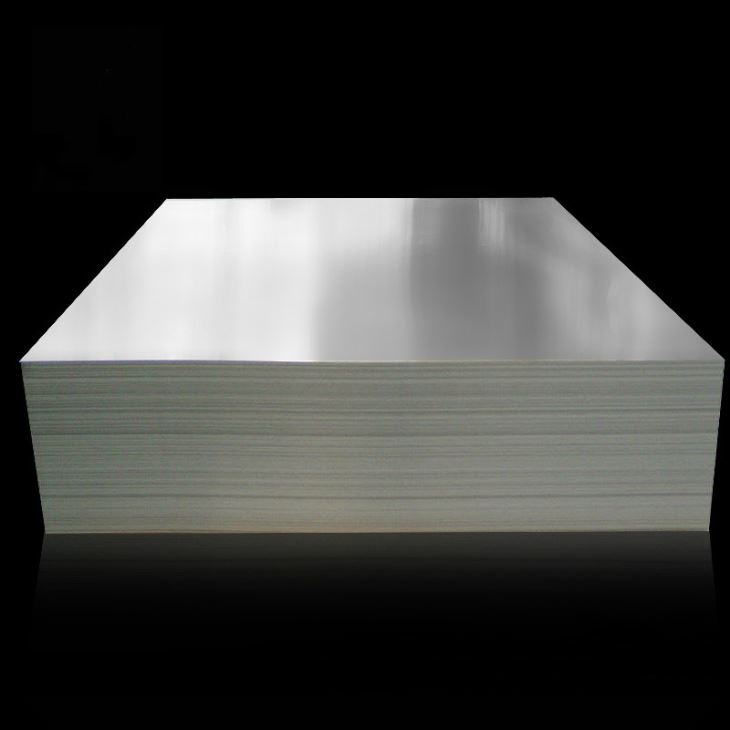

Aluminum busbar (or aluminum bus bar ) is known for their excellent electrical conductivity properties & very good bending properties. These cater to the panels, switchgear, earthing & other electrical bus bar applications & related industries.

Busbar Strength

Some argue that aluminum busbar cannot withstand electromechanical stress as copper busbar. In reality, quality aluminum has plenty of tensile strength to withstand thermal expansion strain.

Depending on the alloying agents employed, the strength of aluminum itself can range from dead soft to mild steel.

Busbar Ampacity

Contingent on busbar size, aluminum busbar can handle currents up to 4000A, which is more than sufficient for many applications.

Busbar Conductivity

Aluminum busbar conductivity is dependent on the alloy and temper. Pure aluminum conductivity(1050 aluminium busbar) is approximately 65.0% of IACS (International Annealed Copper Standard). In fact, when comparing aluminum busbar vs copper, aluminum busbar is twice as conductive as copper.

Busbar Resistance

High quality, high strength aluminum can have mechanical resistance up to 530 Newton/mm2. Aluminum is fatigue resistant and corrosion resistant. Aluminum also offers easy corrosion removal with simple stripping.

Busbar Weight

Aluminum can be as much as 70% lighter than copper. The lightweight properties make aluminum busbar installation so fast and easy that a single operator can do it. Aluminum busbar weight properties not only allow for ease and convenience, but cost-savings as well.

Busbar Cost

Aluminum busbar cost can be drastically lower than that of copper busbar. Its lightweight properties can provide significant cost-savings in handling costs alone. Aluminum also offers high recyclability, which makes it far less likely to experience market fluctuations or supply scarcity.Aluminum busbar may provide a better, more cost-effective solution depending on application requirements.

Previous: The Origin and Solutions of Burrs& Chatter Marks on Alum

Next: No Information